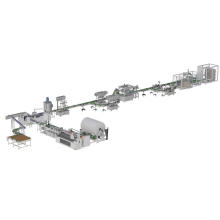

Bottle Line Pharmaceutical IV Solution Filling Production Line

Product Description

Product Description Used for small volume, accurate fills of ultra clean or high value liquids such as reagents, essential oils, pharma preparations and other applications where no cross contamination is permitted. Only low viscosity liquids can be used on this machine.The fluid path is disposable making cleanup very fast and efficient.

Used for small volume, accurate fills of ultra clean or high value liquids such as reagents, essential oils, pharma preparations and other applications where no cross contamination is permitted. Only low viscosity liquids can be used on this machine.The fluid path is disposable making cleanup very fast and efficient.

Detailed Images Bottle unscramblerThis machine is suit for round bottle sorting,it is one of equipment of filling production line. The container is pushed into the bottle sorting machine, and the container can be input to the production line conveying belt one by one through the rotary table rotation, and to enter the next step.

Bottle unscramblerThis machine is suit for round bottle sorting,it is one of equipment of filling production line. The container is pushed into the bottle sorting machine, and the container can be input to the production line conveying belt one by one through the rotary table rotation, and to enter the next step.

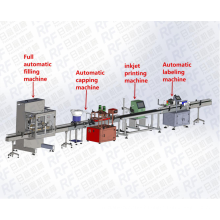

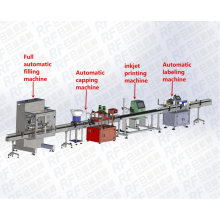

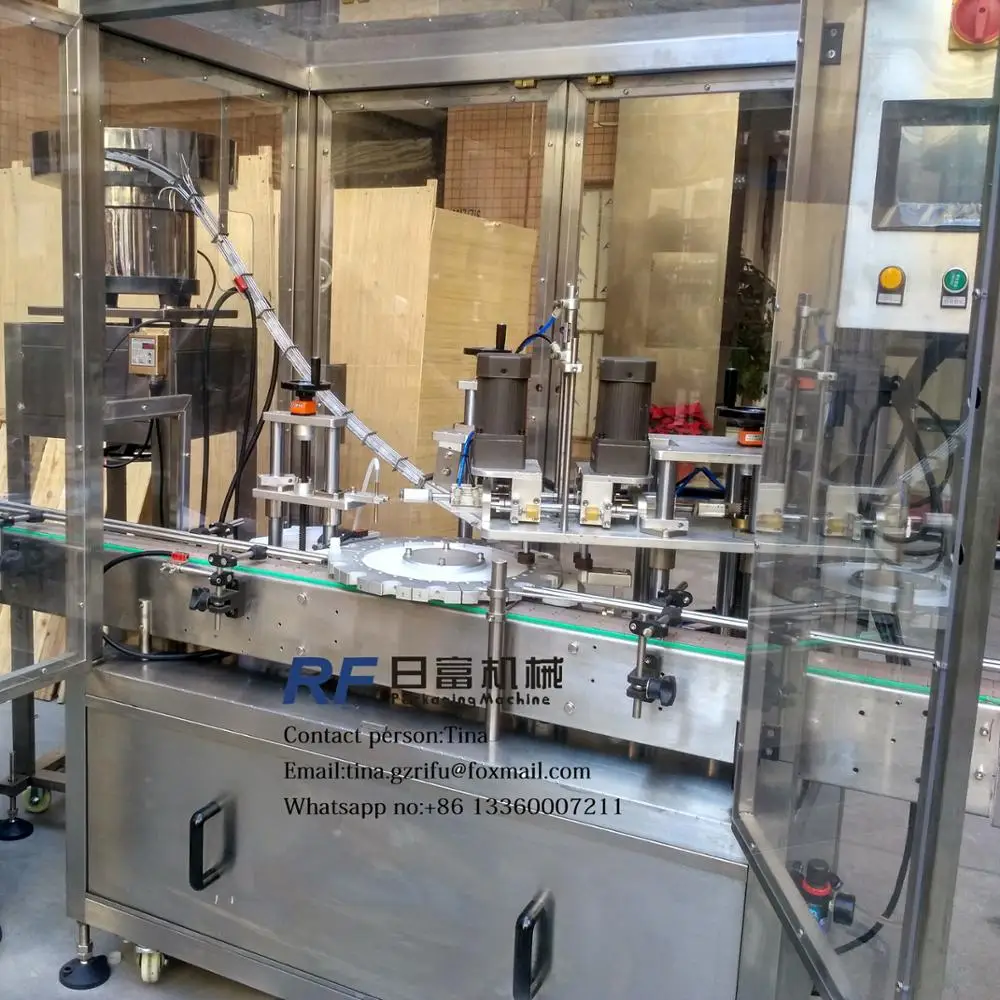

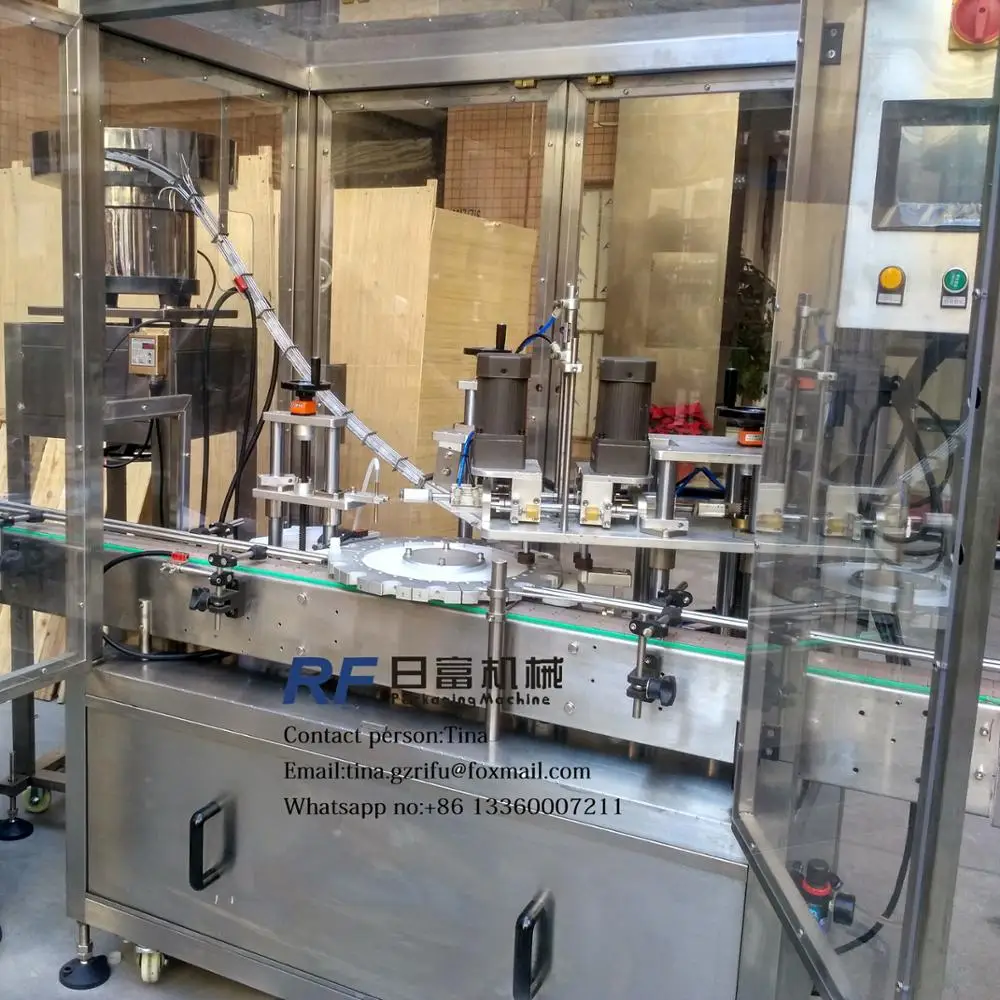

Small volume filling and Capping Machine Liquid quantitative Filling Machine (Universal filling machine) suitable for all kinds of non gas wine, beverages, oil, spices, liquid drugs and other liquid quantitative filling.This machine can be used for all kinds of bottle type.Easy to operate and maintain.

Small volume filling and Capping Machine Liquid quantitative Filling Machine (Universal filling machine) suitable for all kinds of non gas wine, beverages, oil, spices, liquid drugs and other liquid quantitative filling.This machine can be used for all kinds of bottle type.Easy to operate and maintain.

Features:

1.Adopts constant speed, equal graduation and constant pressure principle,has high accuracy.

2.All parts that come into contact with the filled liquid are made of stainless steel or nontoxic polypropylene material, which ensures that the liquid is not contaminated and meets the food hygiene standards.

3.The driving parts are arranged in the frame, the structure is compact, the operation is stable, and the voice is small.

4.The quantitative control valve is equipped with a fine adjustment mechanism to facilitate fine tuning filling.

Labeling machineRF-200 automatic Labeling Machine can be used for round bottle and flat bottle.It can also be equipped with printer synchronous complete label print.And the machine adopts computer optical fiber control,synchronous tracking.This automatic Packaging Machine is controlled by mutual inductor,ensures the synchronization speed of the labeling and rolling bottle.It is a modern mechanical and electrical integration products,with excellent and reliable performance.The machine has many merits,such as clean,beautiful and solid labels,high production,etc.

Labeling machineRF-200 automatic Labeling Machine can be used for round bottle and flat bottle.It can also be equipped with printer synchronous complete label print.And the machine adopts computer optical fiber control,synchronous tracking.This automatic Packaging Machine is controlled by mutual inductor,ensures the synchronization speed of the labeling and rolling bottle.It is a modern mechanical and electrical integration products,with excellent and reliable performance.The machine has many merits,such as clean,beautiful and solid labels,high production,etc.

Technical supportHow to choose filling machine?There are many different technologies and capacities of filling machines available on the world market. It is possible to fill many products on more than one type of filling machine. Choosing the best Liquid Filling Machine for your application is a complex decision based on a host of factors including product characteristics, container characteristics, fill size, daily production needs, plant environment, regulatory issues and hardware cost versus performance.There are many types of filling machine,piston filling machine,gravity filling machine,weighing filling machine,overflow filling machine and so on.And several factors can help you to judge which filling machine is suitable for your product.1.Liquid viscosity2.Corrisive3.Foamy4.Explosion proof5.Silk or drop

You can refer to the following chart.A=excellent B=good C=fair or unlikely D=poor N/A=not available

Related Products PISTON FILLING MACHINEUsed primarily for thick viscous liquids and/or particulated products with limited changeovers. Examples include liquid soaps, cosmetics and heavy food sauces where positive displacement or high pressure filling is required. Also excellent for volumetric filling of expensive products where high accuracy is needed. Higher capital cost but even small machines can produce very high output.

PISTON FILLING MACHINEUsed primarily for thick viscous liquids and/or particulated products with limited changeovers. Examples include liquid soaps, cosmetics and heavy food sauces where positive displacement or high pressure filling is required. Also excellent for volumetric filling of expensive products where high accuracy is needed. Higher capital cost but even small machines can produce very high output.

OVERFLOW FILLING MACHINEThe most widely used filling machine in small bottle filling operations because it handles a wide range of liquids at a modicum of cost. Ease of cleaning, ease of setup and expandable output makes this machine a favorite of growing companies. Used for free flowing liquids with very small to no particulates, it is adept in foam control and often used in fill-to-level glass applications.

OVERFLOW FILLING MACHINEThe most widely used filling machine in small bottle filling operations because it handles a wide range of liquids at a modicum of cost. Ease of cleaning, ease of setup and expandable output makes this machine a favorite of growing companies. Used for free flowing liquids with very small to no particulates, it is adept in foam control and often used in fill-to-level glass applications.

TIME GRAVITY FILLING MACHINEUsed for water thin liquids with no particulates and whose bulk density and flow characteristics do not change with atmospheric or temperature changes. Usually specified in chemical environments where recirculation is not practical. The time gravity filler is an effective low cost technology with limited flexibility.

TIME GRAVITY FILLING MACHINEUsed for water thin liquids with no particulates and whose bulk density and flow characteristics do not change with atmospheric or temperature changes. Usually specified in chemical environments where recirculation is not practical. The time gravity filler is an effective low cost technology with limited flexibility.

NET WEIGH FILLING MACHINEScale based filling system used for products sold by weight. Can be used for bulk products sold in totes and pails as well as for precise weights of smaller volume products that have a very high manufactured value. Output is typically lower with a higher capital cost on this type of filler.

NET WEIGH FILLING MACHINEScale based filling system used for products sold by weight. Can be used for bulk products sold in totes and pails as well as for precise weights of smaller volume products that have a very high manufactured value. Output is typically lower with a higher capital cost on this type of filler.

PERISTALTIC FILLING MACHINEUsed for small volume, accurate fills of ultra clean or high value liquids such as reagents, essential oils, pharma preparations and other applications where no cross contamination is permitted. Only low viscosity liquids can be used on this machine.The fluid path is disposable making cleanup very fast and efficient.

PERISTALTIC FILLING MACHINEUsed for small volume, accurate fills of ultra clean or high value liquids such as reagents, essential oils, pharma preparations and other applications where no cross contamination is permitted. Only low viscosity liquids can be used on this machine.The fluid path is disposable making cleanup very fast and efficient.

Packing & Delivery Packaging Detail:1.Outside package:Standard export wooden cases

Packaging Detail:1.Outside package:Standard export wooden cases

2.Inner packag:Stretch film

Our Company

Our Company Order guide There are many types of filling machine,we need to know more details about your products in order that we can recommend the most suitable machine for you.Our questions as below:1.What's your product?Please send one picture to us.2.Packaging type?Bottle,pail or bag?Please tell us the size too.3. What is weight or bulk?4.Do you have requirement of capacity?

Order guide There are many types of filling machine,we need to know more details about your products in order that we can recommend the most suitable machine for you.Our questions as below:1.What's your product?Please send one picture to us.2.Packaging type?Bottle,pail or bag?Please tell us the size too.3. What is weight or bulk?4.Do you have requirement of capacity? FAQQ1: Are you a trading company or a manufactory?

FAQQ1: Are you a trading company or a manufactory?

A1: We are a manufactory, we supply the factory price with good quality, welcome to visit !

Q2: What’s your guarantee or the warranty of the quality if we buy your machines?

A2: We offer you high quality machines with 1 year guarantee and supply life-long technical support.

Q3: When can I get my machine after I paid?

A3: The delivet time is based on the exact machine you confirmed.

Q4: How do you offer technical support?

A4: 1.Technical support by phone, email or MSN/Skype around the clock

2. Friendly English version manual and operation video CD disk

3. Engineer available to service machinery overseas

Q5:How do you work your after sales service?A5:Normal machine is properly adjusted before dispatch. You will be able to use the mchines immediately.

And You will be able to get free training advice towards our machine in our factory. You will also get free suggestion and consultation, technical support and service by email/fax/tel and lifetime technical support.

Q6: How about the spare parts?

A6: After we deal down all the things , we will offer you a spare parts list for your reference.

Contact us if you need more details on Iv Solution Filling. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Iv Solution Filling、Iv Solution Filling. If these products fail to match your need, please contact us and we would like to provide relevant information.

Contact us if you need more details on Iv Solution Filling. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Iv Solution Filling、Iv Solution Filling. If these products fail to match your need, please contact us and we would like to provide relevant information.

Used for small volume, accurate fills of ultra clean or high value liquids such as reagents, essential oils, pharma preparations and other applications where no cross contamination is permitted. Only low viscosity liquids can be used on this machine.The fluid path is disposable making cleanup very fast and efficient.

Used for small volume, accurate fills of ultra clean or high value liquids such as reagents, essential oils, pharma preparations and other applications where no cross contamination is permitted. Only low viscosity liquids can be used on this machine.The fluid path is disposable making cleanup very fast and efficient.Detailed Images

Bottle unscramblerThis machine is suit for round bottle sorting,it is one of equipment of filling production line. The container is pushed into the bottle sorting machine, and the container can be input to the production line conveying belt one by one through the rotary table rotation, and to enter the next step.

Bottle unscramblerThis machine is suit for round bottle sorting,it is one of equipment of filling production line. The container is pushed into the bottle sorting machine, and the container can be input to the production line conveying belt one by one through the rotary table rotation, and to enter the next step. Small volume filling and Capping Machine Liquid quantitative Filling Machine (Universal filling machine) suitable for all kinds of non gas wine, beverages, oil, spices, liquid drugs and other liquid quantitative filling.This machine can be used for all kinds of bottle type.Easy to operate and maintain.

Small volume filling and Capping Machine Liquid quantitative Filling Machine (Universal filling machine) suitable for all kinds of non gas wine, beverages, oil, spices, liquid drugs and other liquid quantitative filling.This machine can be used for all kinds of bottle type.Easy to operate and maintain.Features:

1.Adopts constant speed, equal graduation and constant pressure principle,has high accuracy.

2.All parts that come into contact with the filled liquid are made of stainless steel or nontoxic polypropylene material, which ensures that the liquid is not contaminated and meets the food hygiene standards.

3.The driving parts are arranged in the frame, the structure is compact, the operation is stable, and the voice is small.

4.The quantitative control valve is equipped with a fine adjustment mechanism to facilitate fine tuning filling.

Labeling machineRF-200 automatic Labeling Machine can be used for round bottle and flat bottle.It can also be equipped with printer synchronous complete label print.And the machine adopts computer optical fiber control,synchronous tracking.This automatic Packaging Machine is controlled by mutual inductor,ensures the synchronization speed of the labeling and rolling bottle.It is a modern mechanical and electrical integration products,with excellent and reliable performance.The machine has many merits,such as clean,beautiful and solid labels,high production,etc.

Labeling machineRF-200 automatic Labeling Machine can be used for round bottle and flat bottle.It can also be equipped with printer synchronous complete label print.And the machine adopts computer optical fiber control,synchronous tracking.This automatic Packaging Machine is controlled by mutual inductor,ensures the synchronization speed of the labeling and rolling bottle.It is a modern mechanical and electrical integration products,with excellent and reliable performance.The machine has many merits,such as clean,beautiful and solid labels,high production,etc.You can refer to the following chart.A=excellent B=good C=fair or unlikely D=poor N/A=not available

PISTON FILLING MACHINEUsed primarily for thick viscous liquids and/or particulated products with limited changeovers. Examples include liquid soaps, cosmetics and heavy food sauces where positive displacement or high pressure filling is required. Also excellent for volumetric filling of expensive products where high accuracy is needed. Higher capital cost but even small machines can produce very high output.

PISTON FILLING MACHINEUsed primarily for thick viscous liquids and/or particulated products with limited changeovers. Examples include liquid soaps, cosmetics and heavy food sauces where positive displacement or high pressure filling is required. Also excellent for volumetric filling of expensive products where high accuracy is needed. Higher capital cost but even small machines can produce very high output. OVERFLOW FILLING MACHINEThe most widely used filling machine in small bottle filling operations because it handles a wide range of liquids at a modicum of cost. Ease of cleaning, ease of setup and expandable output makes this machine a favorite of growing companies. Used for free flowing liquids with very small to no particulates, it is adept in foam control and often used in fill-to-level glass applications.

OVERFLOW FILLING MACHINEThe most widely used filling machine in small bottle filling operations because it handles a wide range of liquids at a modicum of cost. Ease of cleaning, ease of setup and expandable output makes this machine a favorite of growing companies. Used for free flowing liquids with very small to no particulates, it is adept in foam control and often used in fill-to-level glass applications. TIME GRAVITY FILLING MACHINEUsed for water thin liquids with no particulates and whose bulk density and flow characteristics do not change with atmospheric or temperature changes. Usually specified in chemical environments where recirculation is not practical. The time gravity filler is an effective low cost technology with limited flexibility.

TIME GRAVITY FILLING MACHINEUsed for water thin liquids with no particulates and whose bulk density and flow characteristics do not change with atmospheric or temperature changes. Usually specified in chemical environments where recirculation is not practical. The time gravity filler is an effective low cost technology with limited flexibility. NET WEIGH FILLING MACHINEScale based filling system used for products sold by weight. Can be used for bulk products sold in totes and pails as well as for precise weights of smaller volume products that have a very high manufactured value. Output is typically lower with a higher capital cost on this type of filler.

NET WEIGH FILLING MACHINEScale based filling system used for products sold by weight. Can be used for bulk products sold in totes and pails as well as for precise weights of smaller volume products that have a very high manufactured value. Output is typically lower with a higher capital cost on this type of filler. PERISTALTIC FILLING MACHINEUsed for small volume, accurate fills of ultra clean or high value liquids such as reagents, essential oils, pharma preparations and other applications where no cross contamination is permitted. Only low viscosity liquids can be used on this machine.The fluid path is disposable making cleanup very fast and efficient.

PERISTALTIC FILLING MACHINEUsed for small volume, accurate fills of ultra clean or high value liquids such as reagents, essential oils, pharma preparations and other applications where no cross contamination is permitted. Only low viscosity liquids can be used on this machine.The fluid path is disposable making cleanup very fast and efficient.Packing & Delivery

Packaging Detail:1.Outside package:Standard export wooden cases

Packaging Detail:1.Outside package:Standard export wooden cases 2.Inner packag:Stretch film

Our Company

Our Company Order guide There are many types of filling machine,we need to know more details about your products in order that we can recommend the most suitable machine for you.Our questions as below:1.What's your product?Please send one picture to us.2.Packaging type?Bottle,pail or bag?Please tell us the size too.3. What is weight or bulk?4.Do you have requirement of capacity?

Order guide There are many types of filling machine,we need to know more details about your products in order that we can recommend the most suitable machine for you.Our questions as below:1.What's your product?Please send one picture to us.2.Packaging type?Bottle,pail or bag?Please tell us the size too.3. What is weight or bulk?4.Do you have requirement of capacity? FAQQ1: Are you a trading company or a manufactory?

FAQQ1: Are you a trading company or a manufactory?A1: We are a manufactory, we supply the factory price with good quality, welcome to visit !

Q2: What’s your guarantee or the warranty of the quality if we buy your machines?

A2: We offer you high quality machines with 1 year guarantee and supply life-long technical support.

Q3: When can I get my machine after I paid?

A3: The delivet time is based on the exact machine you confirmed.

Q4: How do you offer technical support?

A4: 1.Technical support by phone, email or MSN/Skype around the clock

2. Friendly English version manual and operation video CD disk

3. Engineer available to service machinery overseas

Q5:How do you work your after sales service?A5:Normal machine is properly adjusted before dispatch. You will be able to use the mchines immediately.

And You will be able to get free training advice towards our machine in our factory. You will also get free suggestion and consultation, technical support and service by email/fax/tel and lifetime technical support.

Q6: How about the spare parts?

A6: After we deal down all the things , we will offer you a spare parts list for your reference.

Contact us if you need more details on Iv Solution Filling. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Iv Solution Filling、Iv Solution Filling. If these products fail to match your need, please contact us and we would like to provide relevant information.

Contact us if you need more details on Iv Solution Filling. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Iv Solution Filling、Iv Solution Filling. If these products fail to match your need, please contact us and we would like to provide relevant information. Product Categories : Filling Capping Labeling Production Line > Filling Capping Labeling Production Line

Premium Related Products

Other Products

Hot Products

High quality building Automatic Portable Wall Plastering MachineNew products of manual cap sealing machineMT-50D semi auto sticker labeling machine for round bottlenew Hot sale Color Ribbon Electric Batch Code Printing Machine HP-241BMini Desktop Air Cushion Machine for Automatic Pillow Filling MachineHDPE recycled plastic garbage bag making machineXBF-500 Manual Pvc Blister Paper Sealing Packing MachineChina Coal Small Portable Handheld Inkjet Printer with low price2017 TB-390 multifunction skin packaging machine Body-machine battery packaging machineStainless steel solid-ink coding continuous band sealer with best priceShandong China Coal Group Layers Composite Air-Bubble Film Machine PE2017 Mini Full Auto Strapping Machine PriceDZ500S best vacuum sealer for food storage/Chamber Vacuum SealerAutomatic PVC Heat Tunnel Shrink Packaging Machinetwo heads automatic liquid filling machineJelly Sachet Juice Filling Packing Machine